- Choosing a selection results in a full page refresh.

Couldn't load pickup availability

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Brand Name: NoEnName_Null

Origin: Mainland China

Certification: NONE

Features: foot switch

Model Number: ZHHG-LS3

Item Type: Ultraviolet lamps

Voltage: 85-265V

Average Life (hrs): 20000

Attention: This lamp needs to be used in conjunction with UV eyelash glue to achieve rapid curing effect

This lamp does not have a rapid curing effect on ordinary glue

odel: ZHHG-LS3

Power: 5W

Voltage: AC85-260V

Use life: 20000-30000 hours

Wavelength: 365-395nm

Material:metal

Adjustable light spot size

Adjustable light spot size

Lamp cap size : 60mm

Adjustable hose : 600mm

Vertical hard tube : 1100mm

Round chassis : 240mm

Application of uv lamp:

Application of uv lamp:

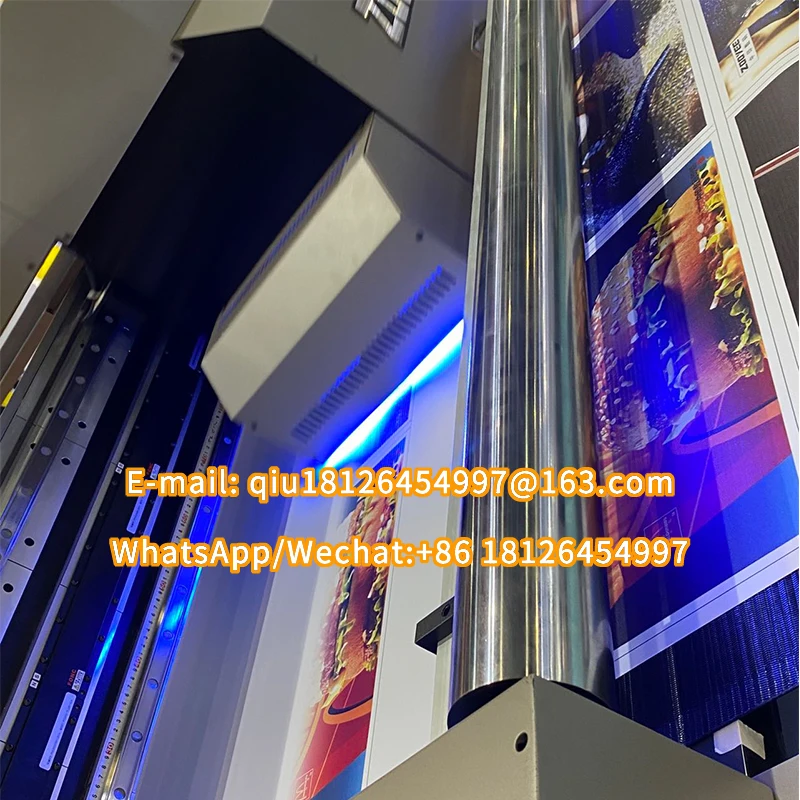

UV LED curing liquid cooling lamp applied to the UV flatbed printer/printing machine/screen printing machine/pad printing machine/offset printing machine/flexo printing machine/bronzing machine/coating machine/character machine/PCB board printing/High-speed character machine/ digital inkjet printer, etc.

It is suitable for UV ink、UV ink、UV varnish、UV paint、UV glue、UV shadowless glue、electronic glue、circuit board printing、PCB circuit board、 green oil printing、various label printing、soft film bronzing、UV electronic glue、shadowless glue dring and curing.

UV LED curing lamps suitable for Epson, Ricoh, Konica, Kyocera, Seiko, VARNISH printhead .

The standard wavelength of UV LED chip is 395nm ,The wavelength can be customized according to customer requirements.

Our company products:

UVLED lamp lighting test:

UVLED lamp application:

Company shipment packaging:

Company Profile:

Our company is headquartered in Shenzhen, Guangdong Province. It is a professional provider of UVLED application solutions integrating R&D, production, sales and after-sales.

At present, corresponding integrated solutions have been launched for the fields of digital printing, compact system, wood processing, wire cross-linking, glue drop plastic, silk screen offset printing, etc.

Won the recognition and trust of well-known manufacturers around the world. In particular, the printing industry has been widely promoted around the world.

Professionally provide UVLED application solutions. Existing solutions include UVLED surface light source, UVLED line light source, UVLED point light source, irradiation light source, Single Pass light source, plastic drop light source...

Our values are "integrity", "innovation", "speed" and "gratefulness". Through the attitude of "service first", we will "create a win-win situation" with customers and partners, and become an innovative and sustainable company.

UVLED common problems and troubleshooting:

1. The whole set of UV lamps is not on

1.1. First check whether the UV control box is turned on, and the control panel button operation indicator is working normally.

1.2. When the power button switch of the UV lamp is on, the green indicator light of the UV power supply is on. If it does not light up, check whether the button switch is damaged and whether the fuse is blown.

1.3. First check whether the connecting wires of the UV control box are dropped, poor contact and loose. The water pipe and water path are blocked, and the water path is blocked, and the display of the main board of the refrigerator is displayed.

1.4. Check whether there is 3-24V at the signal line end of the control line or whether the signal line end of the short-circuit control line is connected. Whether the main board control signal output is normal.

1.5. If there is no problem with the control signal terminal, you can observe the solid-state indicators from the outside of the machine. If all the solid-state indicators are not on, there may be no 3-24V switch small power supply signal input. Check whether the line is dropped. and loose. Note: If the water circuit is blocked, the main board of the refrigerator will display a fault code, which will also cause all solid-state indicators to be off.

2. Two UV lamps only turn on one lamp

2.1. Check whether there is power supply voltage signal input at the signal line end of the control line or whether the signal line end of the short-circuit control line is connected. Also observe that the internal solid state indicator light is on and off.

2.2. Check whether the UV lamp power supply cable is loose or not. This is an interchangeable connection to judge the damage of the UV lamp. If the replacement lamp can be turned on, it means that there is no problem with the UV lamp.

2.3. Check whether the UV lamp power supply cable is broken.

3. A UV light only lights up half or not for a period

3.1. Check whether the UV lamp power cord is correct, there are 4 cores or 6 cores, whether the power cord is inserted incorrectly, and whether the cable is broken.

3.2. Check that the solid-state indicator is on and off. If it is not on, check the power supply voltage at both ends of the solid-state relay to see if there is a power supply voltage input. Detection method: the black meter of the multimeter touches the negative pole of the switch small power supply, and the red pen touches the positive terminal of the solid state relay output. Touch the negative terminal of the output of the solid-state relay. If the output of the solid-state relay has voltage on the positive pole and there is no voltage on the negative output terminal, the solid-state relay is broken (you can test it without power on. If the output terminal is connected, it must be broken. (Breakdown) Under normal circumstances, several of its terminals are blocked (measured with a multimeter when it is not energized), and the appearance is not easy to judge. When the circuit is connected, the voltage drop at both ends can be measured. If the pressure drop is large in the case of pass, it must be broken.

4. There is condensation on the UV lamp head

This phenomenon is mainly because the temperature of the water tank of the UV lamp is set too low, which causes the temperature difference between the indoor and the lamp head to be too large. The solution is to adjust the temperature of the water tank to be close to the indoor temperature.

5. Power regulation

Adjust the appropriate UV lamp power according to different materials of customers. Improper adjustment of the power is too large to easily cause material deformation, and too small power will cause the phenomenon of non-drying.

6. UV light flashes

Check whether the solid state relay is normal and whether the power cord is damaged.

Discover our hottest new arrivals to stay ahead of the style curve.

Thanks for subscribing!

This email has been registered!

| Product | SKU | Description | Collection | Availability | Product Type | Other Details |

|---|